Treatment and recovery of hydrocarbon solvents

Transform solvent challenges into opportunities

In the complex world of pharmaceutical manufacturing, effective management of hydrocarbon solvents is crucial for maintaining product quality, ensuring regulatory compliance, and minimizing environmental impact. With stringent purity requirements, safety concerns, and the need for cost-effective solutions, solvent recovery can be a daunting challenge. Veolia's mobile solvent recovery solutions are here to transform your approach to hydrocarbon management in pharmaceutical processes.

Key benefits:

Environmental responsibility and versatility:

Our versatile solutions effortlessly handle a wide spectrum of hydrocarbon solvents and complex mixtures, ensuring you're always compliant and ready for any process challenge.

Efficiency:

Our energy-efficient technologies optimize recovery processes, balancing effectiveness with sustainability to keep your operations lean and green.

Cost-effectiveness and integration:

Our compact, modular systems integrate smoothly into your existing facilities, minimizing disruption while maximizing environmental responsibility.

Reliability and flexibility:

Whether you're facing an emergency or planning maintenance, our rapid deployment keeps you running. Plus, our scalable solutions adapt swiftly to fluctuations in wastewater volume and composition, ensuring you're always prepared for changing production needs or unexpected challenges.

Expert support and training:

We're not just providing equipment – we're offering ongoing training and support to empower your staff and optimize your water treatment processes.

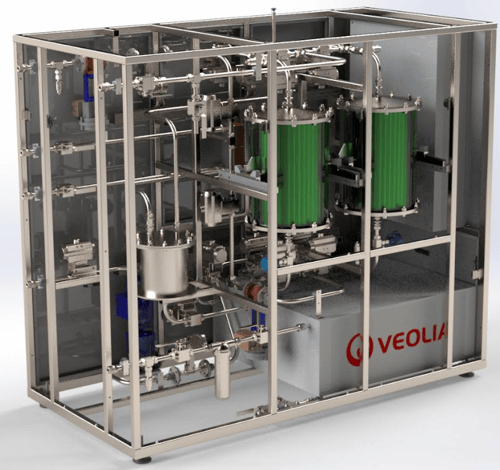

Macro Porous Polymer Extraction/Sorption or MPPE/S technology offers an innovative and comprehensive solution for treating and recovering hydrocarbon solvents from pharmaceutical wastewater streams, addressing the complex needs of modern drug manufacturing facilities.

This highly efficient process can remove a wide range of solvents, including non-polar types like toluene and chlorinated solvents, with remarkable removal efficiencies of up to 99,99%. Such high performance ensures that even trace amounts of solvents can be effectively eliminated, meeting the most stringent regulatory requirements and environmental standards.

The MPPE/S system's versatility in handling diverse solvents makes it particularly valuable for pharmaceutical manufacturers dealing with multiple product lines or varying production processes. Whether it's batch production of different drugs or continuous manufacturing processes, MPPE can adapt to changing wastewater compositions, providing consistent performance across different operational scenarios.

Moreover, the technology not only ensures compliance with stringent environmental regulations but also enables solvent recovery. This dual functionality potentially transforms a waste management challenge into a resource recovery opportunity, aligning with circular economy principles and potentially offering cost savings through solvent reuse or resale.

With its compact design and small footprint, the MPPE system can be easily integrated into existing pharmaceutical facilities, minimizing disruption to ongoing operations. Its low energy consumption, particularly when compared to traditional steam stripping methods, contributes to reduced operational costs and a lower carbon footprint.

Macro Porous Polymer Extraction/Sorption is designed to be an environmentally friendly choice

High recovery rates (up to 99.99%) for various organic solvents

Effective for a wide range of organic compounds

Low energy consumption compared to alternative technologies

No chemicals required for the extraction process

Small footprint

API removal from pharmaceutical wastewater

Tackle the complex challenge of API removal in pharmaceutical wastewater with Veolia's innovative mobile solutions. Our advanced evaporation technology effectively handles a wide spectrum of APIs, with a reduction of over 99% ensuring environmental responsibility.

Let's get in touch!

With Veolia's mobile solvent recovery solutions, you can focus on what you do best – developing and manufacturing life-saving pharmaceuticals – while we ensure your solvent management meets the highest standards of efficiency, safety, and sustainability.

Don't let solvent management challenges compromise your production efficiency or environmental compliance.

-%20C.png?width=150&height=150&name=Blue%20-%20Chemical%20product%20(test%20tube)-%20C.png)